Identification of Kapok Fiber

Release time:

2025-01-17

Kapok fiber is a highly lignified organic seed fiber, a typical cellulose fiber characterized by thin cell walls, large lumen, low density, and hydrophilic properties. As a renewable natural plant fiber, kapok fiber has rich biocompatibility and biodegradability, and its extensive exploration and application in academic and industrial fields are receiving increasing attention. Due to its unique characteristics, kapok fiber-based materials open up possibilities for various new application areas.

Kapok fiber is abundantly produced in Guangdong, Guangxi, and Hainan provinces of China, as well as in Southeast Asian countries, with a wide range of sources, mainly in white, yellow, and yellow-brown colors. The composition of kapok fiber mainly includes cellulose, hemicellulose, and lignin, along with components such as pectin and wax. Generally, the cellulose content of natural cotton fiber is over 90%, with almost no lignin, while kapok fiber can have lignin content up to 20%, hemicellulose up to 45%, and a cellulose content of less than 50%. Therefore, in terms of chemical composition and content, kapok fiber differs significantly from natural cotton fiber.

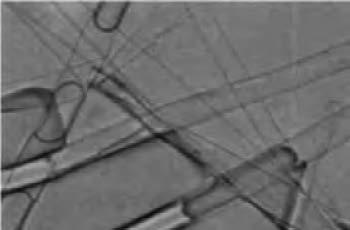

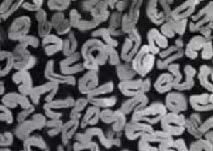

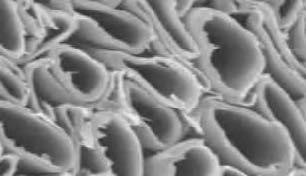

Kapok fiber not only differs in chemical composition from natural cotton fiber, but its surface morphology also varies from cotton and chemical fibers. The surface morphology of kapok fiber is different from that of cotton and polyester fibers; kapok fiber has thin walls and high hollowness, without the curvature seen on cotton fiber surfaces.

Identification of Kapok Fiber

1. Combustion Method

The industry standard FZ/T 01057.2 in China specifies a combustion method for identifying textile fibers, detailing the combustion state when close to the flame, in contact with the flame, and away from the flame, as well as the odor emitted and the characteristics of the residue after burning. The combustion characteristics of kapok were found to be identical to those of cotton fiber as described in this standard. Therefore, the combustion method can be used for sensory identification when the composition is relatively simple and when kapok and cotton do not coexist. It can also serve as a supplement to other qualitative methods or be combined with other identification methods to confirm the type of fiber.

2. Microscopy Method

Research shows that from a biological perspective, kapok is closer to hemp fiber, while differing more from cotton fiber. However, the microscopic structure is quite the opposite; the physical structure of kapok fibers is more similar to that of cotton fibers. Kapok fibers are cylindrical, with a smooth and straight longitudinal shape and uniform fineness. Unlike cotton fibers, which appear flattened and twisted, kapok fibers have thinner walls and higher transparency, allowing for the visibility of water droplet-like cavities. This characteristic is reflected in microscopic images as lighter internal colors (higher grayscale values) and darker edge colors (lower grayscale values). Overall, the grayscale distribution of kapok fibers is relatively uniform. The transverse cross-section of kapok fibers is approximately round with thin cell walls, indicating that there is no secondary cell wall cellulose deposition on the surface of kapok fibers, while the transverse cross-section of cotton fibers is oval with slightly thicker cell walls and smaller cavities, resulting in a much lower density of kapok fibers compared to cotton fibers.

3. Dissolution Method

Through chemical reagent methods, the content of kapok in non-woven fabrics blended with polyester was studied, revealing that kapok fibers do not dissolve in dilute acids and weak bases at room temperature, indicating a certain degree of chemical stability. In 2023, the State Administration for Market Regulation and the National Standardization Administration jointly released a standard for quantitative chemical analysis methods for mixtures of kapok and other fibers, namely GB/T 42695-2023. This standard details various qualitative and quantitative identification methods for kapok fibers, playing a crucial role in the operability of detection and ensuring the accuracy and stability of results, which has significant practical implications.

More information

2025-01-17

Yemeng Company Kapok Series Products

2025-01-17

YD015A LUNACEL Lunacel Series Fabric

2025-01-16

YZ005SK LUNACEL Lunacel Series Fabric

2025-01-16

2025-01-16

YZ020 LUNACEL Lunacel Series Fabric

2025-01-16